Mixing of fermentation substrate in biogas plants via a nozzle mixer for better maintainability

Industrial mixing is used as a basic operation of mechanical process engineering in many pharmaceutical, chemical and biochemical processes. Biogas fermenters, in which the gas-producing fermentation substrate is kept in motion by stirring, are an application that has grown considerably in recent years. Maintenance work, replacement of spare parts or other work in the harsh, anaerobic environment of the fermenter involves a great deal of effort. The aim of the project is to develop a mixer design without internal parts based on a nozzle system, which makes maintenance and repair work much easier and more cost-effective.

This alternative approach to classic stirring creates convection in the mixing vessel by means of dedicated removal and supply of liquid volumes using inlet and outlet nozzles.

Project background

The development of a mixer based on nozzles without internal moving parts reduces ongoing operating costs for maintenance and repair. This increases the competitiveness of biogas plants.

Project objective

An alternative approach to mixing fermentation substrate in biogas fermenters is being developed as part of the project. Functionality and technical feasibility on a large scale are the overarching goals and serve as the basis for the market launch of a new product.

Project procedure

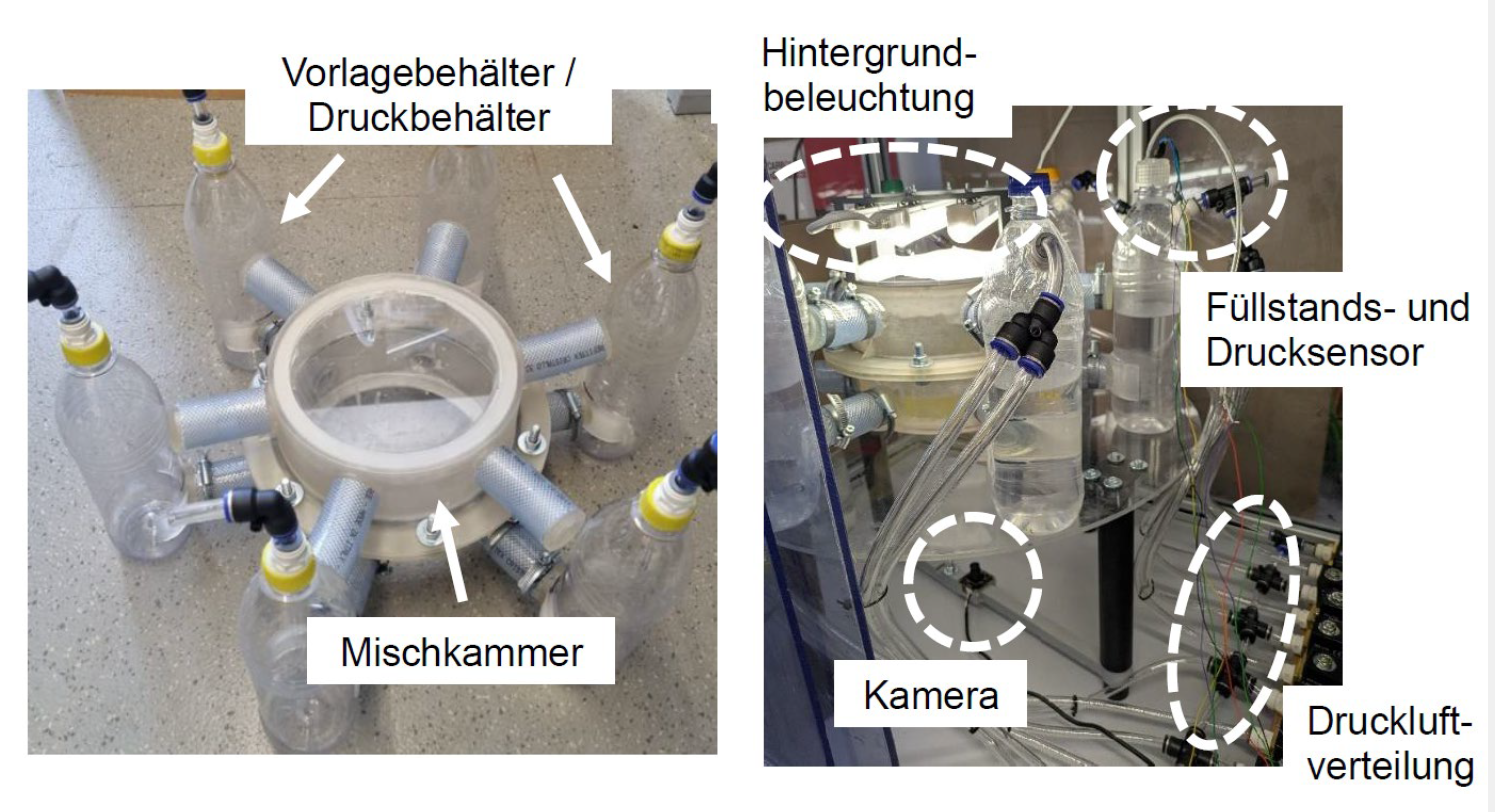

First, numerical flow simulation is used to analyze the generation of flows within a mixing tank. Based on this, tests are carried out in an experimental setup on a laboratory scale with 1.4 L (see Figure 1).

Convection in the mixing tank is achieved by the dedicated removal and supply of liquid volumes from several storage tanks, which are connected to the mixing tank. Solenoid valves open the compressed air supply and push volumes from external containers into the container in a time-periodically controlled manner via nozzle geometries. They also remove specific volumes from the mixing container by lowering the pressure in the supply containers. The operating parameters pressure and fill level as well as video sequences of the particle movement in the mixing chamber are recorded continuously.

After processing the raw video data (see Figure 2), a velocity distribution is determined by software-based evaluation of the particle paths (see Figure 3). The operating parameters and the velocity distribution are used to evaluate the efficiency of the mixing process.

Innovation

The elimination of internal moving parts and the resulting reduction in maintenance costs make biogas plants more economical. This also reduces the number of times workers need to enter the inside of the plant, which lowers the risk of accidents at work. This benefits manufacturers, suppliers and operators of biogas plants.

Project lead

Project staff

T +49 (0) 8031 / 805 - 2943 benedikt.schwarz[at]th-rosenheim.de

External project collaboration

AiF Projekt GmbH

Propellertechnik Maier GmbH

Project duration

2024-12-01 - 2026-11-30Project partners

Project management agency

Project funding