FoWoCo (Foamed Wood Composites): Foamed fiber composites made of wood fibers and biopolymers for technical lightweight construction applications

Foamed fiber composites made from wood fibers and biopolymers for lightweight construction applications

Project background

The project idea is to develop foamed fiber composites with wood fibers and bioplastics. Bioplastics in combination with wood fibers can be used to produce biocomposites that are based 100% on renewable raw materials. The wood fibers serve not only as a filler but also as a reinforcing fiber.

By foaming the structures, the weight of the fiber composite can be further reduced in order to fully exploit the lightweight construction potential. The high weight of plastics with wood is still a problem. The raw materials used in this project are not only renewable raw materials but also recycled renewable raw materials such as waste materials from the paper and wood industry.

Project objective

The aim is to investigate the potential of foamed structures made of bioplastics in combination with wood fibers and to bring them to market maturity. This involves developing new materials (base polymer, additives, blowing agent and wood fibers), investigating properties using test specimens, applying them to an end product and using a demonstrator to prove potential market readiness.

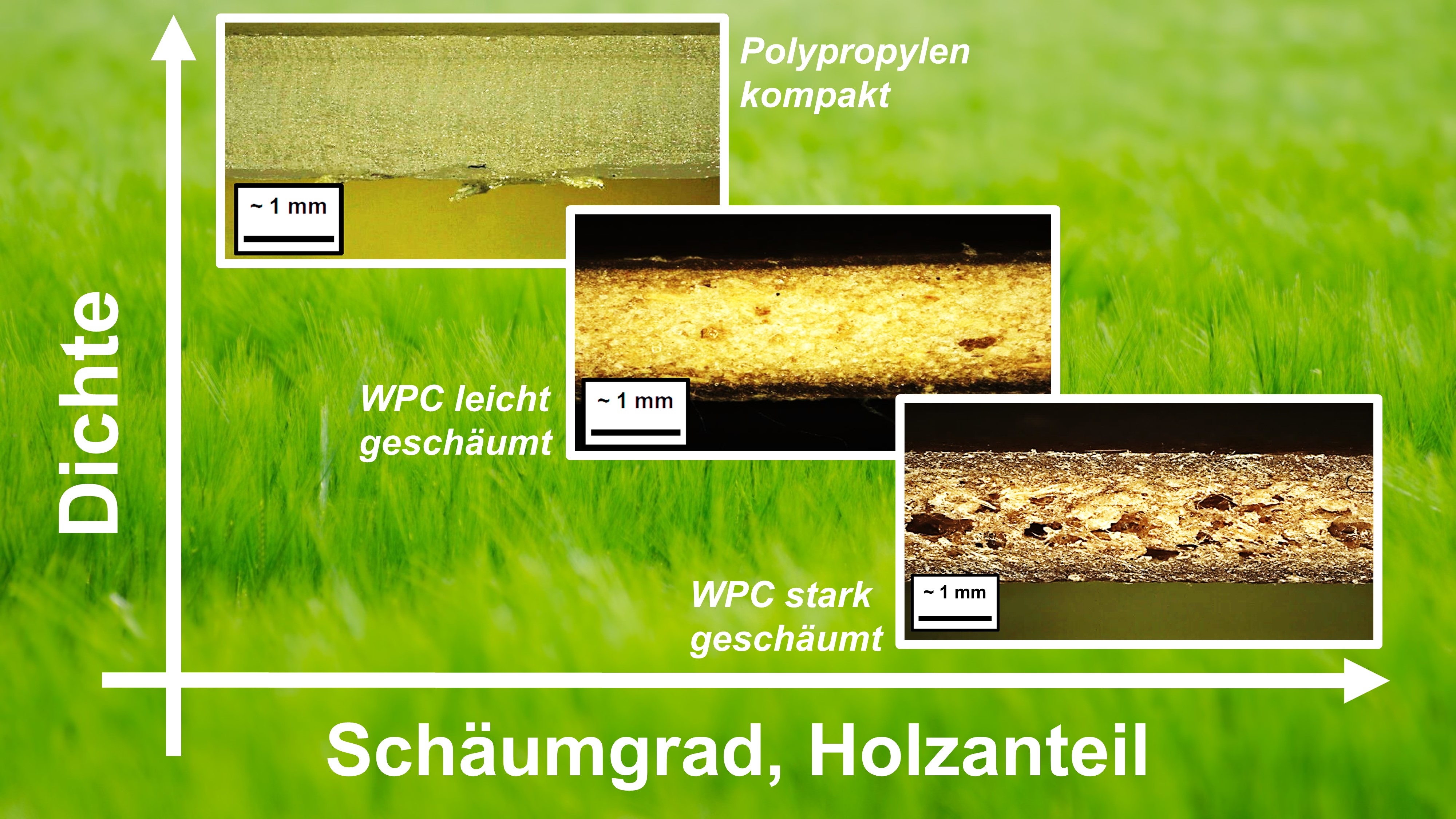

The current disadvantage of plastics with wood is their high weight. With a filler content of 30% spruce fibers by weight, the density of polypropylene increases from 0.9 g/cm³ to approx. 1.2 g/cm³ depending on processing. In addition, wood is usually only used as a filler in so-called WPCs (wood-plastic compounds) in combination with plastics. The potential of wood as a reinforcing fiber is therefore currently not used. Furthermore, only standard polymers from fossil sources are usually used for WPCs. The wide range of biopolymers still receives little attention.

Project procedure

- Use of biopolymers from paper industry waste (ARBOFORM®) and other biopolymers (ARBOBLEND®: PHA, PCL, Bio-PET, PLA, Bio-PE, Bio-PA) for foaming in injection molding in combination with wood fibers

- Development of a biopolymer-based blowing agent

- Application of the material via inline foam extrusion on an end product (construction element for e.g. carports)

- Implementation on a demonstrator component (full use of the lightweight construction potential, high wall thicknesses, large wall thickness jumps, high torsional rigidity and crash properties, strengthening of the foam structure through wood fibers, high acoustic damping behavior, long flow paths, high wall thickness jumps at the end of the flow path, implementation of functional elements as well as snap hooks and film hinges)

Innovation

Possible areas of application for the material include technical components, the automotive industry and the furniture and construction industries. Such components have rarely been used to date, as the density of the material is very high and processing is difficult. The implementation with foamed biopolymers and wood-reinforcing fibres should maximize the sustainability concept, exploit lightweight construction potential and thus promote the further development, acceptance and market maturity of biocomposites. Material combinations of wood and plastic or bioplastic can thus be significantly improved.

The SME consortium partners thus have the opportunity to further develop existing products and processes. In addition, completely new business areas can be opened up and sales markets gained. The company Novo-Tech (associated partner) currently produces construction elements made from crude oil-based polyethylene foam. They would like to switch to foamed bioplastics with wood fibers. Spritzguss Müller (cooperation partner) is planning to implement the innovative material combination in toys for animals.

Project lead

T +49 (0) 8031 / 805 - 2631 peter.karlinger[at]th-rosenheim.de

ORCID iD: 0009-0002-8523-3630

Project staff

T +49 (0) 8031 / 805 - 2266 Frederik.Obermeier[at]th-rosenheim.de

ORCID iD: 0009-0007-6049-9017

Project duration

2021-04-01 - 2023-09-30Project partners

Project funding