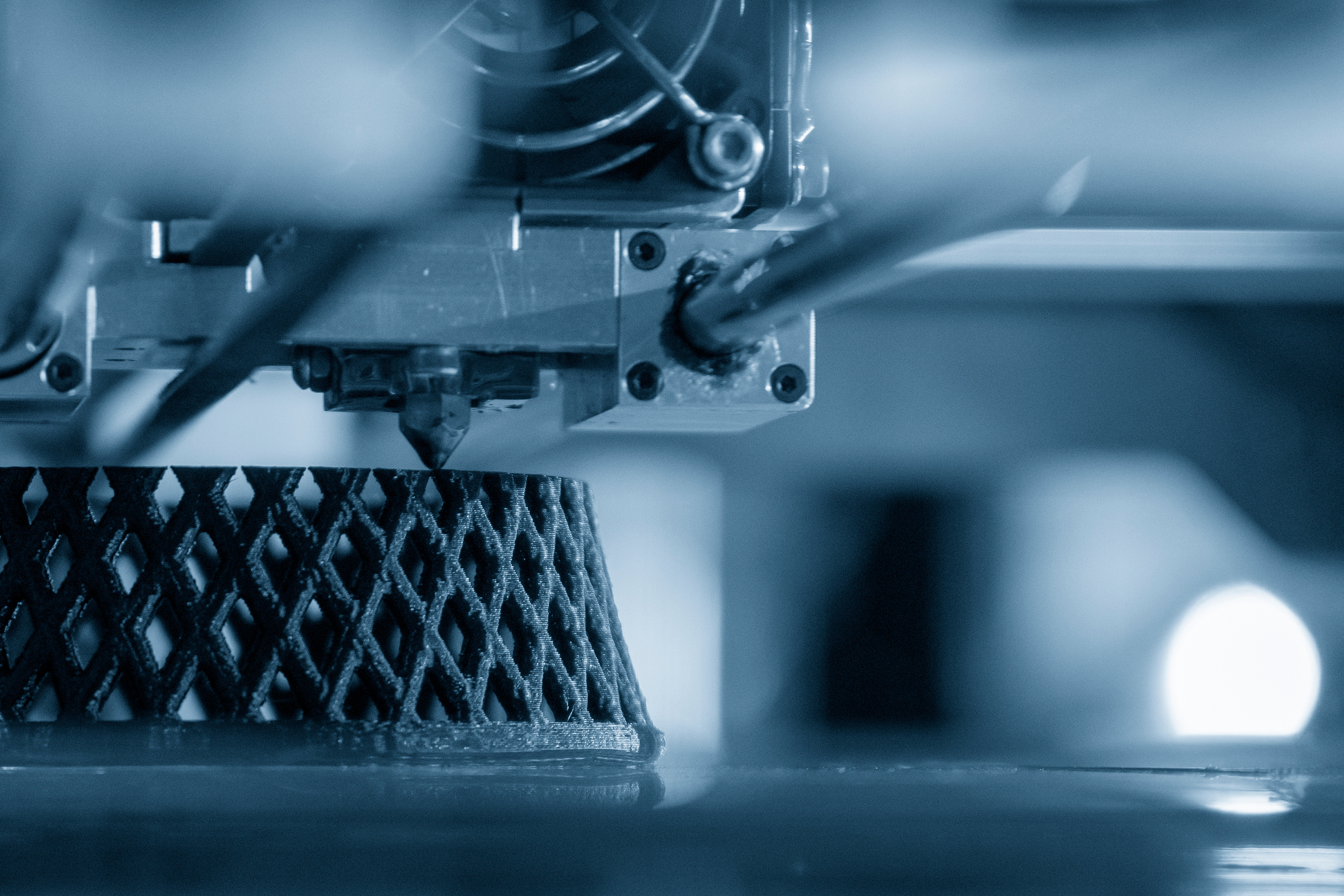

Chemical expansion foaming of TPE

Chemical expansion foaming with high wall thicknesses and adjustable degrees of foaming for the overmolding of thermoplastic elastomers on different carrier plastics.

Project background

This project aims to economically produce components with a soft-touch surface made of chemically foamed thermoplastic elastomers on different carrier plastics. The soft-touch surface determines the feel of the finished product and the carrier plastic takes over the functionality. In addition to the feel, the degree of foaming determines the weight reduction.

Project objective

The project aims to combine the advantages of lightweight construction and resource efficiency with the functionalization of products. This can be achieved with a targeted cost reduction in production. The accompanying functionalization through the soft-touch surface not only saves an additional work step, but also makes this process extremely attractive.

Innovation

The chemical foaming of thermoplastic elastomers allows production in a one-shot process with low investment costs, which means that the chances of market entry can be assessed as high. Compared to current processes, the low investment costs allow for profitable use in small to medium batch sizes.

In the small to medium batch size range, functionalization is often not financially feasible, as this is offset by the often high investment costs. The low investment costs therefore significantly multiply the chances of market entry.

Project lead

T +49 (0) 8031 / 805 - 2631 peter.karlinger[at]th-rosenheim.de

ORCID iD: 0009-0002-8523-3630

Project staff

T +49 (0) 8031 / 805 - 2361 Markus.Zillmer[at]th-rosenheim.de

Project duration

2019-01-01 - 2021-05-31Project partners

Project management agency

Project funding