DBU_reversible wood-concrete composite ceilings

Timber-concrete composite floors have been used for more than 100 years. Until now, the bond between the timber web and the concrete slab was maximized with the help of cerves, bolts, screws, shear plates or adhesives. All of these conventional, high-strength bonding methods cannot be dismantled, or only with considerable difficulty, and are therefore unsuitable for a circular construction industry. In this project, an attempt is being made to produce a new type of bond between wood and concrete that requires few or no screw connections. This new generation of wood-concrete composite ceilings should enable complete dismantling with subsequent, separate reuse of the building materials wood and concrete in the future.

Project background

The construction industry and conventional construction produce immense amounts of waste and are therefore still miles away from a circular economy. The aim of this project is to the following using a wood-concrete composite ceiling:

- the dominance of concrete in the construction industry is to be reduced and replace concrete as far as possible with the renewable raw material wood

- the deconstructability factor of standard building components such as wood-concrete composite ceilings should be brought to the attention of architects and civil engineers

- The first constructions of a deconstructable wood-concrete wood-concrete composite ceiling are to be tested for stiffness and failure in the component press.

Project objective

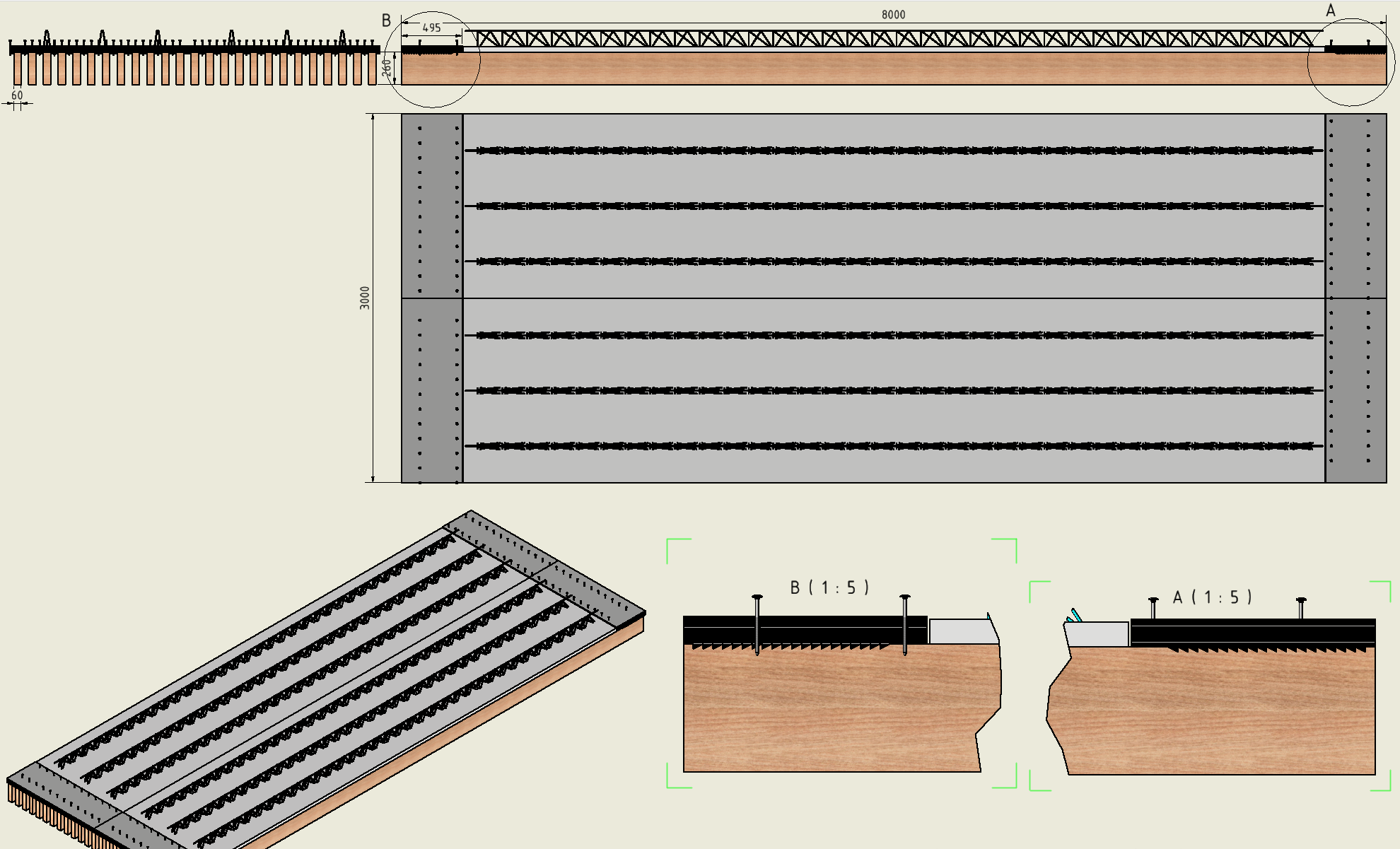

In multi-storey buildings, pure concrete ceilings and wooden ceilings have long been standard. The advantages of wood and concrete as building materials can also be combined in a so-called wood-concrete wood-concrete composite ceiling, which is therefore a hybrid component. In the wood-concrete composite ceiling beams are used, which provide the bending tensile strength for the the bending tensile stresses for the reinforced concrete slab above.

A timber-concrete composite floor thus combines the advantages of the individual material properties of concrete and wood. The focus of research to date has been on achieving the most shear-resistant shear-resistant bond between the concrete slab and timber beam in the form of screws, cerves, flat steel locks or shear plates. The disadvantage of all these shear connectors lies in the associated non-separability of the building materials after the the end of the building's service life.

In this project, deconstructability is now to be included for the first time in the catalog of requirements for wood-concrete composite ceilings. The aim is to develop constructions for wood-concrete composite ceilings which can be dismantled, but which have a similar performance to conventional as previous, conventional constructions.

Project procedure

The aim is to develop a new type of bond between the timber web and concrete flange that can be dismantled, but is in no way inferior to a conventional timber-concrete composite slab in terms of load-bearing capacity and stiffness. Practical laboratory experiments are carried out in two test series in the hydraulic component press at Rosenheim Technical University of Applied Sciences:

a) Testing of shear connections that are tested for shear failure.

b) Testing of wood-concrete composite floor elements that are tested for bending and shear failure.

Innovation

A deconstructable wood-concrete composite floor represents a major step towards a circular construction industry, in which the equivalent reuse of building materials and components building materials and components replaces the previously practiced energy recovery of (waste) wood and the crushing of concrete into granulate. Both wood and concrete should be equally reusable in a second life. A deconstructable wood-concrete composite floor therefore represents a substantial contribution to sustainable construction in a closed circular economy.

Project lead

Sub-project lead

T +49 (0) 8031 / 805 - 2387 johann.pravida[at]th-rosenheim.de

Project staff

ludwig.gredmeier[at]th-rosenheim.de

Project collaboration

torben.geipel[at]stud.th-rosenheim.de

Project duration

2024-01-01 - 2025-05-31Project partners

Project management agency