Opti-Zent: Investigation of pomace digestion in centrifugation via experiment and simulation with innovative screw geometry to increase the yield

When producing vegetable oils or fruit juices with 2-phase decanters, approx. 80-90% of the oil or juice can be extracted in high quality. To significantly reduce the loss, the processes involved in dehydrating the marc, the rheological behavior of the liquid and the powder flow of the pile will be investigated. Simulations of the discrete element method coupled with flow simulation and thus a new screw geometry for improved extraction of the marc.

Project background

The olive oil production process consists of several steps. After digestion and malaxation, a decanter centrifuge separates the water, olive oil and pomace. This separation step results in the loss of 5 to 15%, which can later only be recovered as oil of inferior quality.

Project objective

The aim of this project is to use the rheological knowledge of olive oil pomace to improve separation in such a way that the amount of olive oil lost can be reduced.

Project procedure

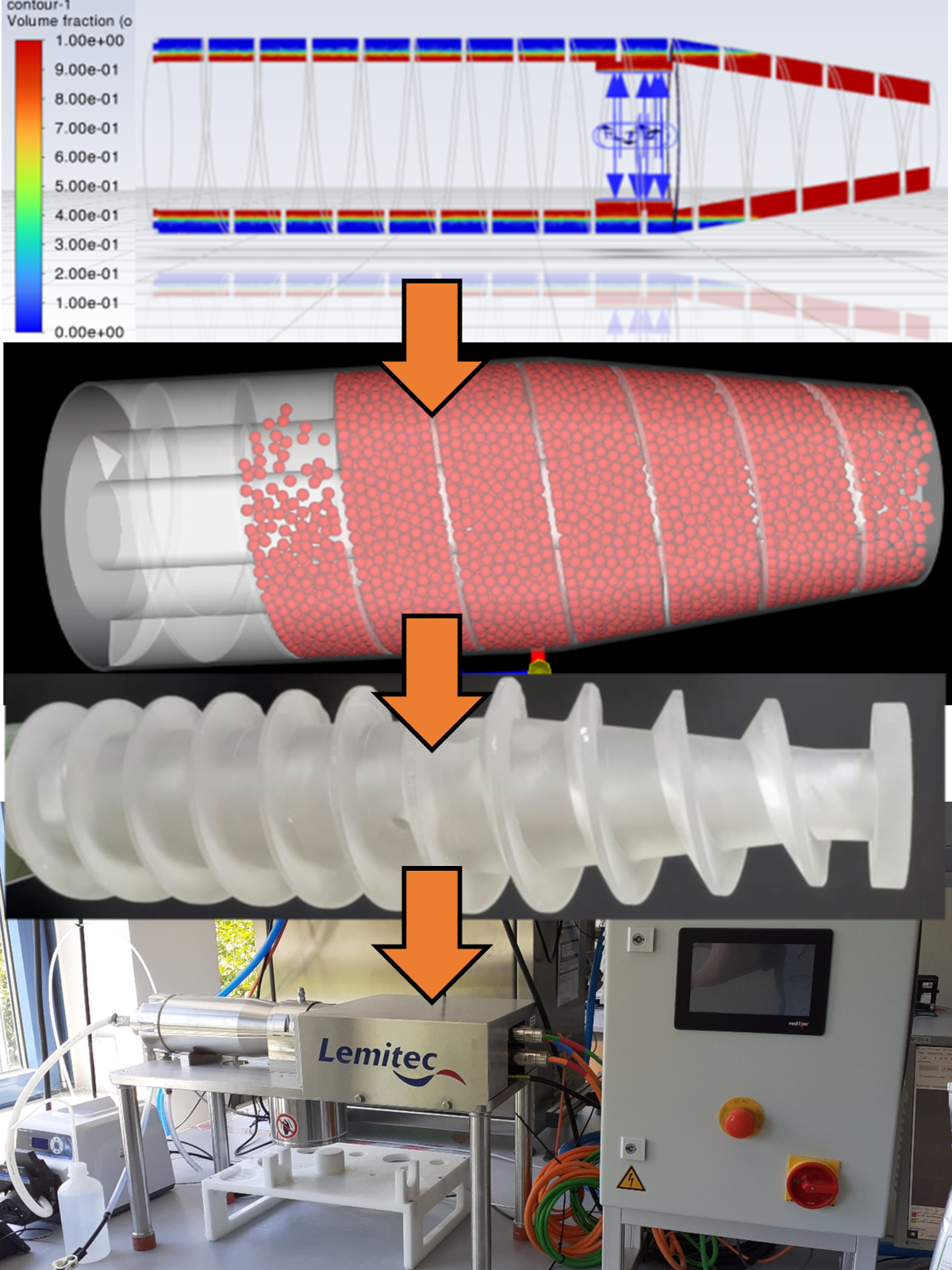

The rheological properties of pomace are investigated in rheometers and ring shear cells. Based on the knowledge of the material then used to simulate the processes in decanter centrifuges. This is carried out using the discrete element method coupled with flow simulation using finite volumes and smoothed particle hydrodynamics. The findings are then implemented and demonstrated experimentally on a laboratory centrifuge. The decanter screw geometries are produced using produced using rapid prototyping and tested with different process media.

Innovation

The objective of the project is, in particular, to determine the rheological properties of olive olive pomace. In addition, the use of rapid prototyping for the generation of prototypes for decanter centrifuges represents new scientific territory. The use of the discrete element method coupled with flow simulation (finite volumes and smoothed particle hydrodynamics) for the the representation of pomace is new in this form. The aim is ultimately new decanter geometries for the processing of pomace.

Project lead

Project staff

tzu-yang.huang[at]th-rosenheim.de

T +49 (0) 8031 / 805 - 2943 benedikt.schwarz[at]th-rosenheim.de

External project collaboration

Bayerische Transformations- und Forschungsstiftung

Bayerische Transformations- und Forschungsstiftung

Project duration

2024-01-01 - 2026-07-31Project partners

Project funding